HSZ-A Type 0.5 Ton Mini Chain Hoist with Manual Operation

| Model | CB-B | ||||||||

| Capacity(ton) | 0.5 | 1 | 1.5 | 2 | 3 | 5 | 7.5 | 10 | |

| Standard lifting height(m) | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3 | 3 | |

| Running test load(ton) | 0.625 | 1.25 | 1.875 | 2.5 | 3.75 | 6.25 | 9.375 | 12.5 | |

| Headroom H(mm) | 345 | 376 | 442 | 470 | 548 | 688 | 765 | 765 | |

| Load chain dia. Columns | 1 | 1 | 1 | 1 | 1 | 2 | 3 | 4 | |

| (mm) | Dia +Pitch | 5×15 | 6×18 | 7×21 | 8×24 | 10×30 | 10×30 | 10×30 | 10×30 |

| Effort to required to lift max.Load(N) | 240 | 245 | 255 | 324 | 363 | 353 | 373 | 380 | |

| Dimension(mm) | A | 148 | 172 | 196 | 255 | 280 | 433 | 463 | |

| B | 132 | 151 | 173 | 205 | 189 | 189 | 189 | ||

| C | 30 | 30 | 36 | 40 | 50 | 56 | 56 | ||

| D | 35 | 37 | 45 | 50 | 64 | 85 | 85 | ||

| Net weight | 9.3 | 12.2 | 16.5 | 19.5 | 32 | 43 | 71.6 | 78.5 | |

| Packing measurements (lxwxh)(mm) | 30×17×18 | 32×18×19 | 37×20×24 | 37×20×24 | 43×40×30 | 47×44×35.5 | 62×47×39.5 | 53×51×46.5 | |

| Extra weight per meter of extra lift(kg) | 1 | 1.3 | 1.6 | 1.9 | 2.8 | 4.1 | 5.9 | 7.8 | |

Company Information

TXK was founded in 1997 with 1.5 million USD registered fund in the very beginning and grow up as a leading manufacturer of electric chain hoist, manual chain hoist, electric wire rope hoist and various lifting and material handling equipment with more than 15 years experience and hard work.Our factory cover an area of 66000 square meters, the biggest workshop in the electric hoist industry in China.Workshop

Testing

Package&Shipping

Plywood cases are neatly placed in the workshop, and each plywood case comes with operating instruction, inspection report, packing order.

When you order 3 sets or more quantity,we usually use a pallet to prevent the goods from damage.This will be easy to arrange shipment.

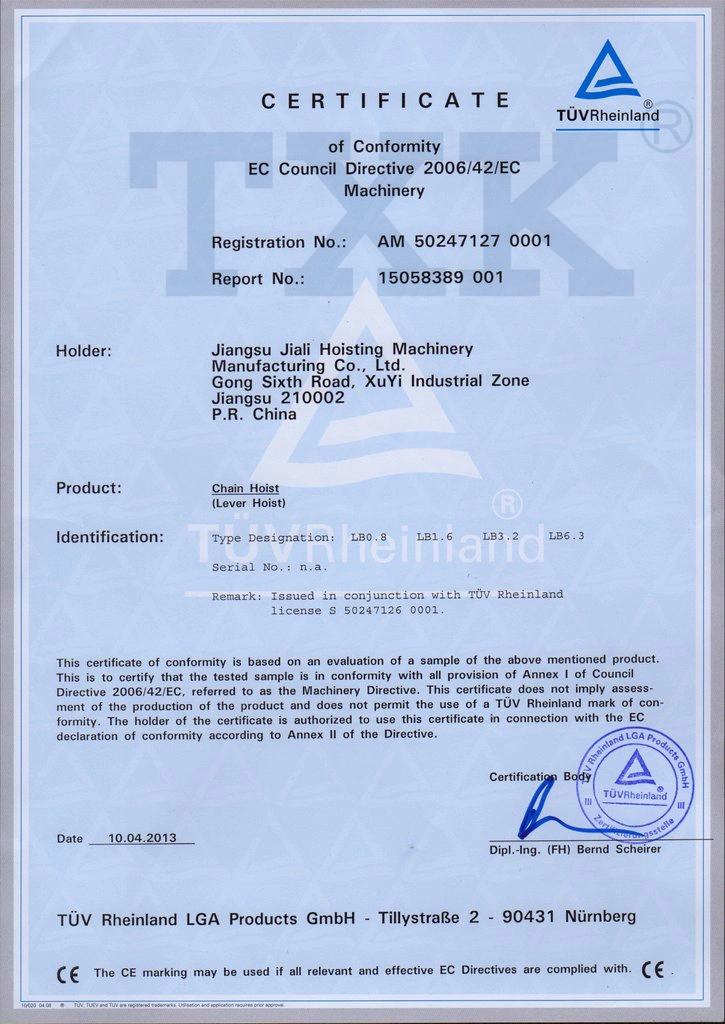

Certificates:

Our company obtained the approval of ISO9001 and CE certification from Europe,and our products have been exported to Europe,America,the Middle East,Africa and Southeast Asia.

FQA:

Q: What's MOQ?

A: MOQ can be 1 set.

Q: How about your payment terms?

A: T/T 100% before production.Or 30% deposit, the balance after B/L copy, we accept T/T and L/C at sight.

Q: What information should I provide if I want to order the products?

A: The information such as the lifting capacity, lifting height, power supply or other specifications you give us will be more appreciated.Inquiry now!

Q: What is your lead time for your goods?

A: Normally within 7 working days after receiving the payment.

Why Choose Us?

1.Guide Roller: It uses forged steel.While some other suppliers' are made of cast iron , they can break cast steel easily .

2.Chain Sprocket: We add roller bearings inside the shaft hole to reduce the friction of the long axis,this provides much lighter pulling force.

3.Pin & Lock Plate:To prevent the pin off,it uses a two-way stop design.

4.Short Axis: It is 5 gears structure, so the coupling between gears can be better.While most suppliers use the ordinary low carbon steel,the service life is short.

5.Friction Plate:We add appropriate amount of metal abrasive.Durable & anti-skidding.

6.High Quality Deep Groove Ball Bearing:Both sides with dust cover,it has long service life.

7.Hook:After forging and heat treatment , the shape is not easy to have deformation.